NABL

Nacharam, Hyderabad - 500 076 | 09949041029 | 7337322821

Industrial Rubber Sheets :

Ameenji Rubber Limited manufactures a comprehensive range of rubber sheeting by using various kinds of polymers and matching all kinds of customer needs. All Ameenji Rubber sheeting products are inhouse tested in their IEC17025 NABL Accredited Lab and also they are CE compliant. Ameenji Rubber’s highly innovative team also offers the development of custom compounds and products for our customers.

We are the foremost rubber products manufacturer in India with a state of the art manufacturing facility in Telangana. We supply our products to all major cities in India and export to the Middle East, European and Western countries.

Storage of the Products :

Storage conditions should be as per DIN7716 standards.

Avoid direct sunlight and proper stacking on pallets & prolonged shelf life under appropriate storing conditions

Forms

- Rolls

- Tiles

Product Dimension :

| SIZES & TOLERANCES | ||||

|---|---|---|---|---|

| SIZES | TOLERANCES ± | SIZES | TOLERANCES ± | |

| Fraction Inches | Decimals Inches | Inches | Milimiters | Milimiters |

| Under 1/32" | Under 0.031 | 0.01 | 1 | +/- 0.1 |

| 1/32" to but not including 1/16" | 0.031 to 0.062 | 0.012 | 2 | +/- 0.2 |

| 1/16" to but not including 1/8" | 0.062 to 0.125 | 0.016 | 3 | +/- 0.3 |

| 1/8" to but not including 3/16" | 0.125 to 0.187 | 0.02 | 5 | +/- 0.5 |

| 3/16" to but not including 3/8" | 0.187 to 0.375 | 0.031 | 10 | +/- 1.0 |

| 3/8" to but not including 9/16" | 0.375 to 0.562 | 0.047 | 15 | +/- 1.4 |

| 9/16" to but not including 3/4" | 0.562 to 0.750 | 0.062 | 20 | +/- 1.5 |

| 3/4" to but not including 1" | 0.750 to 1.000 | 0.094 | 25 | +/-10% |

| 1" and over | 1.000 and over | 10% | 30/40/50 | +/-10% |

| Width Tolerances | +/- 2% | |||

| Length Tolerances | +/- 2% | |||

Rubber Selection Criteria :

| RUBBER SELECTION CRITERIA | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TYPE OF APPLICATION | ||||||||||||

| TYPE OF RUBBER | PETROL | LUBRICATING OILS |

ACIDS | ALKALI | HYDRAULIC/ PHOSPHATES |

FLUID/ SILICATES |

ABRASION RESISTANCE |

TEAR STRENGTH | IMPACT RESISTANCE |

RESILIENCE | IMPERMEABLE TO GLASS |

COMPRESSION SET |

| NATURAL/ SBR |

Poor | Poor | Fair | Fair | Poor | Poor | Excellent | Good | Excellent | Excellent | Fair | Good |

| CHLOROP RENE |

Poor | Fair | Fair | Fair | Poor | Good | Good | Good | Good | Good | Good | Good |

| NITRILE | Good | Good | Good | Fair | Poor | Good | Good | Good | Fair | Good | Good | Good |

| EPDM | Poor | Poor | Excellent | Good | Good | Fair | Good | Fair | Good | Good | Good | Fair |

| BUTYL | Poor | Poor | Excellent | Excellent | Good | Fair | Good | Good | Good | Fair | Excellent | Fair |

| CSM | Poor | Fair | Excellent | Excellent | Fair | Good | Good | Fair | Good | Good | Excellent | Fair |

| SILICONE | Poor | Good | Fair | Fair | Good | Poor | Fair | Poor | Fair | Poor | Poor | Good |

| FKM | Excellent | Excellent | Good | Fair | Poor | Good | Good | Fair | Fair | Fair | Excellent | Good |

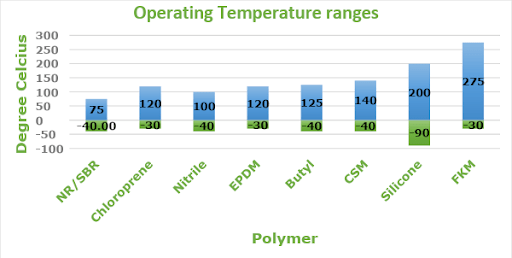

Operating Ranges Of Different Polymers :

Technical Important Note :

The information given above has been derived after years of tests and trials undertaken by our own QC department. As individual operating conditions have a bearing on the application of each sheet, the information on this site can only be used as a guideline. It is the sole responsibility of the customer to evaluate the requirements of sheets, as per their needs and specifications. Products are used entirely at the customers own risk.

© - Copyright. Ameenji Rubber Limited | All rights reserved.